Contents

ToggleSurface finishing is a crucial aspect of CNC machining, where the final appearance, durability, and functionality of the part can be significantly influenced by the type of finish applied. Whether for aesthetic appeal, corrosion resistance, or improved performance, selecting the appropriate surface finish is key to meeting customer specifications and ensuring the part’s longevity. In this article, we will explore the importance of surface finishing, the different methods available, and how each process affects CNC machined parts.

The Importance of Surface Finishing

The primary purpose of surface finishing is to improve the functional properties of a CNC machined part. These functions may include:

- Aesthetic Appeal: A smooth and polished surface enhances the visual appeal of the part, which is especially important for products that will be visible to end consumers. For industries like automotive, medical devices, or electronics, surface finish plays a critical role in product perception.

- Corrosion Resistance: Many CNC machined parts are exposed to harsh environments, including moisture, chemicals, or extreme temperatures. A proper surface finish can significantly enhance a part’s resistance to corrosion, ensuring its performance over time.

- Wear Resistance: For parts that experience high friction or wear, such as gears or bearings, surface finishes can improve the part’s durability by reducing friction and increasing hardness.

- Functional Requirements: In addition to aesthetics and durability, surface finishes can impact a part’s functionality, including its ability to conduct electricity, resist friction, or remain biocompatible in medical applications.

Common Surface Finishing Methods for CNC Machined Parts

Several methods are used to achieve the desired surface quality, each suitable for specific applications and material types. Let’s review the most common surface finishing processes.

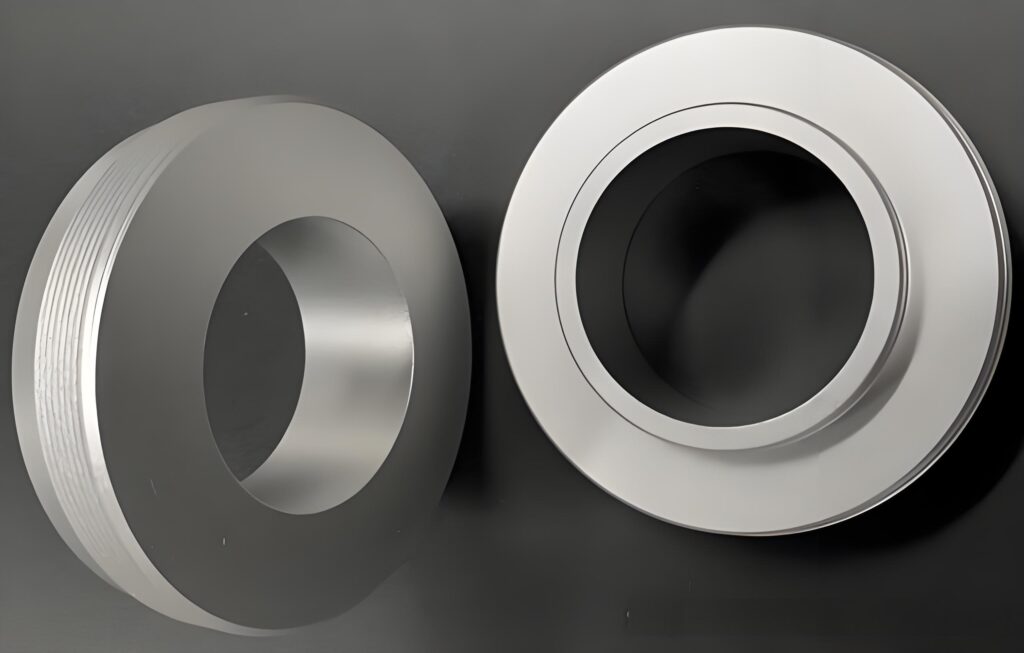

1. Polishing

Polishing is a mechanical process used to achieve a smooth, shiny surface with minimal roughness. This process involves the use of abrasive tools and compounds to remove small imperfections. Polishing is commonly applied to metals and plastics and is ideal for parts where appearance is important, such as in decorative items or medical devices.

Advantages:

- Provides a high gloss finish

- Enhances the appearance of the part

- Suitable for both metals and plastics

Disadvantages:

- Can be time-consuming and labor-intensive

- May not be effective for larger imperfections

2. Anodizing

Anodizing is an electrochemical process commonly used for aluminum parts. It increases the thickness of the natural oxide layer on the surface, which enhances corrosion resistance, wear resistance, and overall durability. Anodized parts can also be dyed for aesthetic purposes, allowing manufacturers to produce parts in various colors.

Advantages:

- Excellent corrosion and wear resistance

- Improved durability and strength

- Possibility of adding color for aesthetic purposes

Disadvantages:

- Limited to aluminum and aluminum alloys

- Can increase dimensional tolerances due to the oxide layer thickness

3. Electroplating

Electroplating involves the deposition of a metal layer onto the surface of a part using an electrical current. This process is widely used to improve corrosion resistance, provide a decorative finish, or enhance hardness. Common materials used in electroplating include gold, silver, nickel, and chrome.

Advantages:

- Excellent corrosion resistance

- Provides a smooth, shiny finish

- Can be used for both decorative and functional purposes

Disadvantages:

- Can increase part cost due to the additional materials and processes involved

- Not suitable for all materials, particularly plastics

4. Powder Coating

Powder coating is a dry finishing process where a powdered pigment is applied to a part, and then it is baked to form a durable finish. This process is commonly used for parts exposed to the outdoors, such as automotive and industrial applications. Powder coating offers excellent resistance to UV light, corrosion, and wear.

Advantages:

- Highly durable and resistant to corrosion, wear, and UV degradation

- Available in a wide range of colors and finishes

- Environmentally friendly, as it does not require solvents

Disadvantages:

- Limited to parts with simple geometries

- Requires a curing oven, which may not be suitable for all production environments

5. Shot Peening

Shot peening is a cold working process where small, spherical media (typically steel or glass beads) are blasted at the surface of a part to induce compressive stress. This process improves the fatigue strength and wear resistance of metal parts, particularly in aerospace, automotive, and heavy machinery applications.

Advantages:

- Increases fatigue strength and durability

- Improves resistance to stress corrosion cracking

- Effective for improving parts subjected to cyclic loading

Disadvantages:

- May alter the part’s surface geometry

- Requires specialized equipment and expertise

6. Bead Blasting

Bead blasting, also known as sandblasting or media blasting, is a process in which abrasive media (such as glass beads or sand) is sprayed at high velocity onto a part’s surface. This method is often used to create a matte or satin finish and improve surface texture.

Advantages:

- Provides a consistent, uniform texture

- Ideal for creating non-reflective finishes

- Suitable for a wide range of materials, including metals and plastics

Disadvantages:

- May not be effective at removing deep scratches or imperfections

- Can create an uneven surface if not properly controlled

Choosing the Right Surface Finish

Selecting the appropriate surface finish for CNC machined parts depends on several factors, including the material, functional requirements, cost considerations, and aesthetic preferences. Manufacturers should carefully assess the part’s application and the environment in which it will be used.

For example, anodizing is ideal for parts exposed to outdoor environments, while polishing is more suitable for high-precision applications requiring a smooth, glossy surface. Electroplating and powder coating are often used in automotive and aerospace industries for their durability and resistance to corrosion. Shot peening, on the other hand, is commonly applied to parts subjected to high-stress conditions, such as gears and turbine blades.

Conclusion

Surface finishing plays a vital role in enhancing the quality, performance, and appearance of CNC machined parts. From improving corrosion resistance and wearability to providing an aesthetically pleasing finish, selecting the right surface treatment is essential for achieving the desired end product. By understanding the various finishing methods available, manufacturers can make informed decisions that meet both functional and aesthetic requirements.RAPIDMFG, as a leader in CNC machining, is committed to providing high-quality parts with optimal surface finishes tailored to meet the specific needs of our customers.