- +86 756-5500888

0

+

Companies ServedDelivering Durable, Custom Metal Solutions for Your Industry

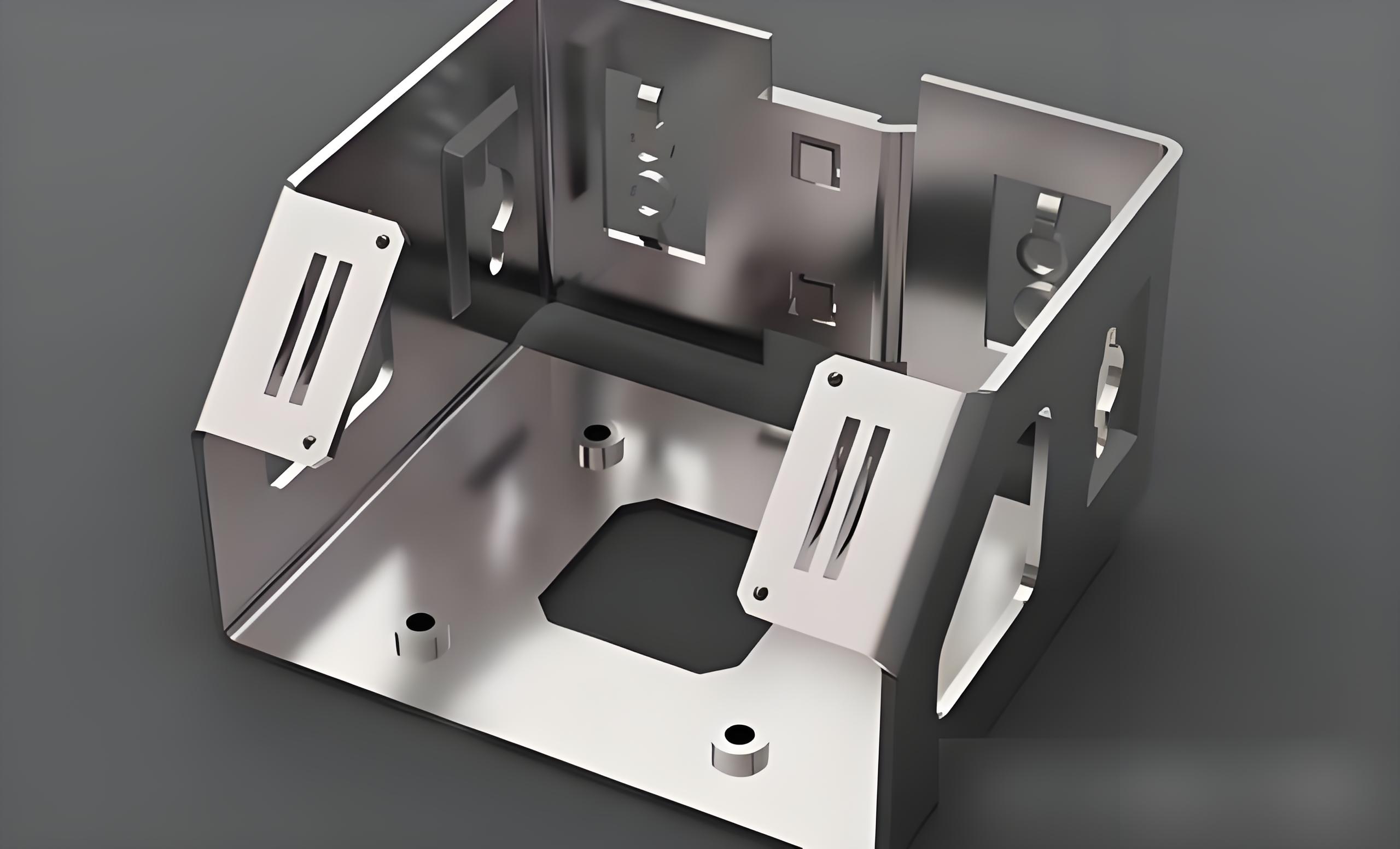

Sheet metal fabrication is a critical manufacturing process that involves shaping, cutting, and assembling thin metal sheets into a variety of components used across different industries. From automotive parts to electronic enclosures, sheet metal fabrication plays a vital role in creating durable, cost-effective, and precise metal products. The most commonly used metals include aluminum, stainless steel, copper, and brass, chosen for their durability, strength, and ease of manipulation.

At RAPIDMFG, we offers sheet metal fabrication services to meet the unique needs of our clients, offering everything from prototyping to full-scale production.

At RAPIDMFG, we provide a comprehensive range of sheet metal fabrication services to ensure your product is crafted with precision and efficiency.

Welding is an essential process in sheet metal fabrication for joining separate pieces of metal together. At RAPIDMFG, we use MIG welding, TIG welding, and spot welding to ensure strong and durable connections. We also offer assembly services where parts are joined together using mechanical fasteners or welding, ensuring structural integrity.

The final touch in sheet metal fabrication is finishing, which enhances both the appearance and the durability of the product. We offer a wide range of finishing options including powder coating, anodizing, electroplating, and paint finishing. These options provide protection against corrosion, wear, and aesthetic enhancement.

Laser cutting provides high precision and clean edges, even for intricate and complex shapes. This method uses a high-powered laser beam to melt, burn, or vaporize material. It’s ideal for creating custom parts with fine details, ensuring accuracy and minimal waste.

Punching is used to create holes, slots, and other features in the metal sheet. This method uses a punch press to drive a tool into the sheet, cutting out specific shapes and designs. It’s a cost-effective method for producing high-volume parts quickly.

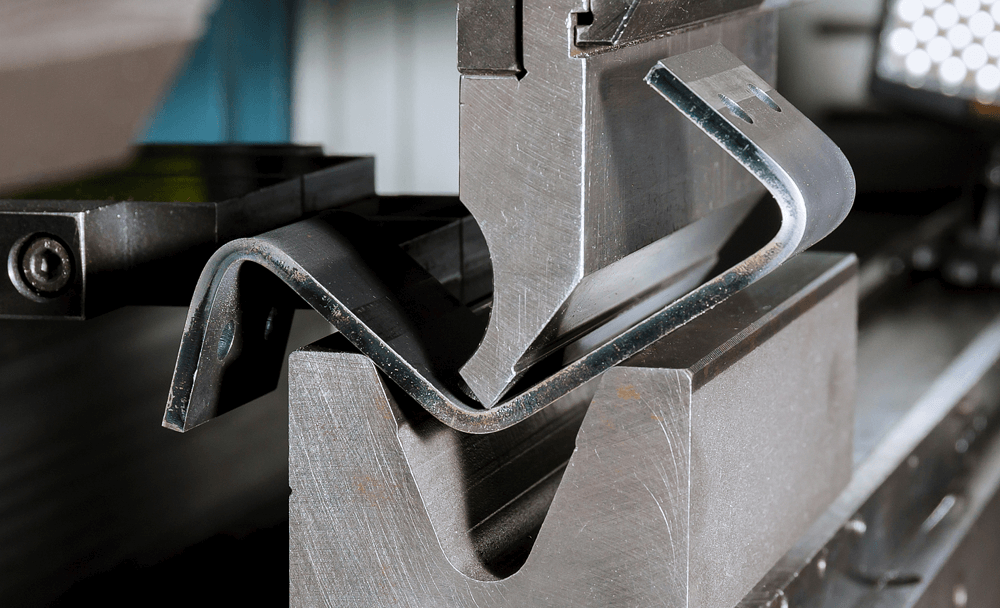

Bending involves shaping the metal by applying force to create precise angles and curves. This process is done using a press brake or rolling machine. It allows for the production of complex geometries, making it suitable for structural components and enclosures.

Durability and Strength: Metal components made from sheet metal are highly durable, providing long-lasting solutions for even the most demanding environments.

Cost-Effectiveness: Sheet metal fabrication is an affordable manufacturing method, particularly for high-volume production. Processes like punching and laser cutting reduce material waste and labor costs, making it ideal for large-scale manufacturing.

Design Flexibility and Precision: Advanced CNC machines allow for high precision in shaping, cutting, and assembling parts. This enables complex and custom designs that meet specific customer requirements.

Rapid Prototyping and Low Volume Production: Sheet metal fabrication allows for quick prototyping and low-volume production, reducing lead times and enabling faster product development cycles.

Fabricated parts such as chassis, body panels, and brackets are essential in vehicle manufacturing.

Lightweight and durable sheet metal components are used in aircraft and space applications, including fuselages, wings, and structural supports.

Metal enclosures for computers, servers, and consumer electronics are produced using sheet metal fabrication.

Structural components such as beams, columns, and roofing systems are fabricated from sheet metal for commercial and residential buildings.

Precision-made parts, such as casings for medical equipment, require high-quality sheet metal fabrication for safety and performance.

Working with RAPIDMFG is easy and efficient. Our streamlined process ensures clear communication and smooth project execution from start to finish. Here’s how it works:

Sharing your project details, including design files, material and surface finish requirements, and production goals. Our team will review the information and provide initial feedback.

Based on your requirements, we’ll provide a detailed quote outlining costs, lead times, and manufacturing processes.

Once the quote is approved, our design team will create custom molds, and prototypes will be produced for your approval.

After prototype approval, we begin full-scale production. Our team ensures the highest quality standards are maintained throughout the process.

We rigorously test and inspect every step to ensure it meets your specifications and is ready for use.

Upon completion, we deliver the final product on time and provide ongoing support for maintenance or future modifications.

With a focus on precision, speed, and cost-efficiency, RAPIDMFG helps bring your product ideas to life faster and with guaranteed quality.

Partner with RAPIDMFG for manufacturing solutions that bring your vision to life—faster, better, and more efficiently than ever.

Product Manager at BioMed Solutions

FAQ

Key processes include cutting (laser, plasma, waterjet), bending (press brakes), forming, welding, punching, and finishing (powder coating, painting).

Tolerances typically range from ±0.005 to ±0.020 inches (±0.13 to ±0.5 mm) but vary based on the material, process, and part complexity.

Yes, it is widely used for prototyping due to its precision, quick turnaround times, and ability to produce functional parts that closely resemble production versions.

Sheet metal fabrication shapes flat sheets of metal through cutting, bending, and joining, while machining removes material from a solid block to create parts.

Sheet metal fabrication shapes flat sheets of metal through cutting, bending, and joining, while machining removes material from a solid block to create parts.

FAQ

Key processes include cutting (laser, plasma, waterjet), bending (press brakes), forming, welding, punching, and finishing (powder coating, painting).

Tolerances typically range from ±0.005 to ±0.020 inches (±0.13 to ±0.5 mm) but vary based on the material, process, and part complexity.

Yes, it is widely used for prototyping due to its precision, quick turnaround times, and ability to produce functional parts that closely resemble production versions.

Sheet metal fabrication shapes flat sheets of metal through cutting, bending, and joining, while machining removes material from a solid block to create parts.

Sheet metal fabrication shapes flat sheets of metal through cutting, bending, and joining, while machining removes material from a solid block to create parts.

Sheet metal fabrication is a crucial process in modern manufacturing, offering a versatile solution for creating a wide range of products from flat metal sheets.

Sheet metal fabrication is a versatile and widely-used process in manufacturing that turns metal sheets into useful components for industries ranging from automotive to aerospace.

Sheet metal fabrication is an essential process in the manufacturing of a wide range of products, from automotive parts to electronics enclosures.

Contact Us

Ready to bring your design to life? RAPIDMFG specializes in delivering high-quality manufacturing solutions, from rapid prototyping to full-scale production. Connect with us to explore how we can support your project with efficiency and expertise

No.9 Huangyang 4th Road, Jingan Town, Doumen District, Zhuhai City (R & D Building 2)

+86 756-5500888

Stay updated with our latest news, innovations, and exclusive offers—subscribe to our newsletter today!

GUANGDONG RAPID MFG TECHNOLOGIES LTD

RAPIDMFG has truly exceeded our expectations! Their team provided outstanding support throughout the entire process, from prototype to production. The quality of their CNC machining and injection molding services is exceptional, and they delivered our project faster than we ever anticipated. The level of precision and attention to detail they demonstrated was remarkable. We highly recommend RAPIDMFG for anyone looking for reliable and efficient manufacturing solutions!