Design Tips for Silicone Compression Molding

Silicone compression molding is a widely used process for producing high-quality silicone rubber parts. The process involves placing a pre-measured amount of silicone material into a heated mold cavity, where the material is compressed and cured under pressure to form the desired shape. It’s especially favored for manufacturing products like seals, gaskets, medical devices, and […]

Design Tips for Pressure Die Casting

Pressure die casting is a highly efficient manufacturing process for producing complex metal parts with excellent dimensional accuracy and surface finish. To leverage its full potential, designers must account for specific constraints and opportunities inherent in the process. This article outlines key design tips to optimize parts for pressure die casting, ensuring quality, functionality, and […]

Design Tips for CNC Machining

Computer Numerical Control (CNC) machining is a versatile manufacturing method used to produce precision parts from various materials. To maximize efficiency and ensure high-quality results, designing parts specifically for CNC machining is critical. This article shares practical design tips to help engineers and designers optimize their parts for CNC manufacturing. 1.Select Suitable Materials Material […]

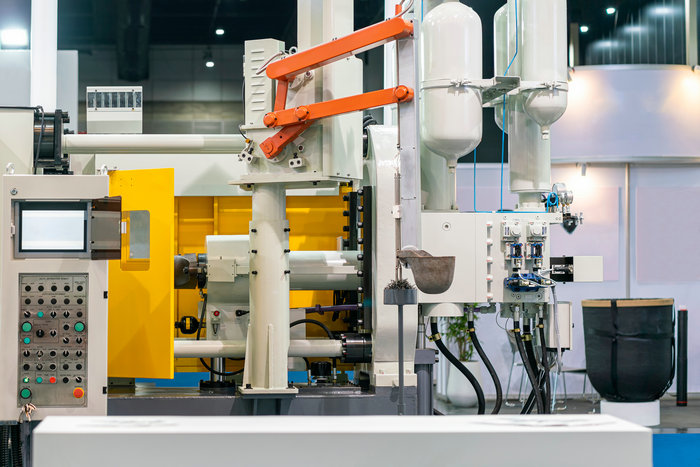

Design Tips for Plastic Injection Molding

Plastic injection molding is one of the most versatile and widely used manufacturing processes for producing high-quality plastic parts at scale. However, achieving precision, functionality, and cost-efficiency hinges on effective design. This article outlines essential design tips for injection molding to help you optimize your parts for manufacturing success. 1.Consider Wall Thickness Uniformity Maintaining […]

How Molds Are Made at RAPIDMFG

At RAPIDMFG, the process of mold making is a combination of advanced technology, precision engineering, and a commitment to delivering high-quality molds tailored to client requirements. Below is a step-by-step breakdown of how we manufacture molds: 1.Design and Engineering Customer Input: We start by gathering detailed specifications, including CAD files, product dimensions, material requirements, […]