Benefits of Silicone Compression Molding for High-Performance Parts

Silicone rubber has long been recognized for its excellent performance in challenging conditions, including high temperatures, chemical exposure, and mechanical stress. As industries increasingly require parts that can meet these rigorous demands, silicone compression molding has become an essential manufacturing method. In this article, we will explore the benefits of silicone compression molding, particularly for […]

Comprehensive Guide of Silicone Compression Molding

Silicone compression molding is a widely used manufacturing process for producing high-precision silicone rubber parts. This method is particularly useful for creating components that need to withstand high temperatures, pressures, or demanding physical conditions. It is commonly used across various industries, including automotive, medical, and consumer electronics. In this article, we will explore the process […]

Surface Finishing Techniques in CNC Machining

Surface finish is a critical aspect of CNC machining, determining not only the appearance of a part but also its performance, functionality, and durability. As industries demand higher quality and tighter tolerances, surface finishing techniques have become increasingly sophisticated. These processes can smooth rough surfaces, improve corrosion resistance, enhance aesthetic appeal, and even alter mechanical […]

Reducing Lead Times in CNC Machining Projects

CNC machining has become an essential technology in modern manufacturing. Whether it’s for producing custom parts for industries like aerospace, automotive, or medical devices, the ability to reduce lead times in CNC machining projects is critical for meeting tight deadlines, staying competitive, and maximizing efficiency. Lead time, the period from the initiation of a project […]

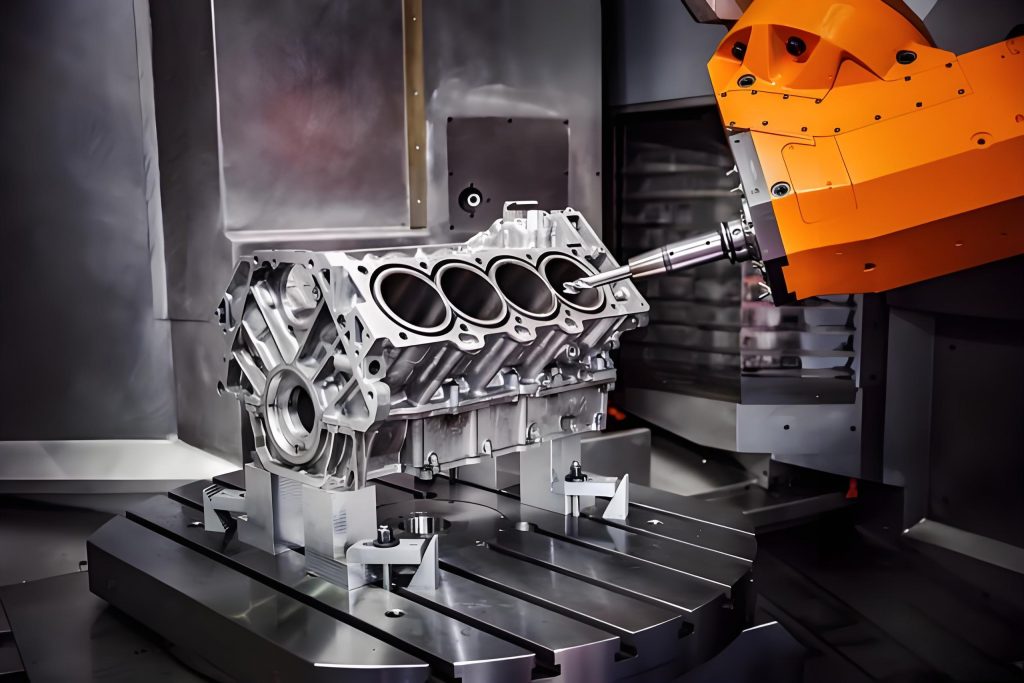

Innovations in 5-Axis CNC Machining

In today’s competitive manufacturing landscape, companies are constantly seeking innovative solutions to improve efficiency, precision, and flexibility. Among these advancements, 5-axis CNC machining has emerged as a cornerstone of modern manufacturing. Unlike traditional 3-axis systems, 5-axis CNC machining allows the cutting tool or the workpiece to move along five different axes simultaneously. This capability not […]

Surface Finishing Options for Aluminum Die Cast Parts

Aluminum die casting is a widely used manufacturing process known for its precision and efficiency in producing complex, high-quality parts. However, the quality and appearance of aluminum die castings are often enhanced through various surface finishing techniques. Surface finishing not only improves the visual appeal of the part but also plays a crucial role in […]

How to Choose the Right Aluminum Alloy for Die Casting

Aluminum die casting is one of the most widely used methods in manufacturing lightweight and durable metal parts. From automotive components to consumer electronics, aluminum die casting is favored for its ability to produce precise, intricate parts at high volumes. However, the success of an aluminum die casting project heavily depends on choosing the right […]

Die Casting vs. CNC Machining: Which is Right for Your Project?

When it comes to precision manufacturing, selecting the right process for your project is critical to ensure both efficiency and quality. Two of the most common techniques used in the manufacturing industry today are die casting and CNC machining. Both methods offer distinct advantages, but they are suited to different types of projects based on […]

Understanding the Importance of Mold Flow Analysis in Injection Molding

Mold flow analysis is a critical tool for predicting and optimizing the flow of molten plastic during injection molding. This article explains how it helps prevent defects, optimize cycle times, and enhance part quality, making it an indispensable part of modern injection molding processes. In the injection molding industry, achieving consistent quality and efficiency […]

Common Defects in Injection Molded Parts and How to Solve Them

Injection molding defects, such as warping, sink marks, short shots, and flash, can impact product quality and manufacturing efficiency. This article identifies the causes of these defects and provides actionable solutions, emphasizing the importance of mold design, material selection, and process optimization in minimizing issues. Injection molding is a widely used manufacturing process that […]